Contents[hide] |

[edit] Design and equipment

Recording studios generally consist of three rooms: the studio itself, where the sound for the recording is created (often referred to as the "live room"), the control room, where the sound from the studio is recorded and manipulated, and the machine room, where noisier equipment that may interfere with the recording process is kept. Recording studios are carefully designed around the principles of room acoustics to create a set of spaces with the acoustical properties required for recording sound with precision and accuracy. This will consist of both room treatment (through the use of absorption and diffusion materials on the surfaces of the room, and also consideration of the physical dimensions of the room itself in order to make the room respond to sound in a desired way) and soundproofing (to provide sonic isolation between the rooms). A recording studio may include additional rooms, such as a vocal booth - a small room designed for voice recording, as well as one or more extra control rooms.

Equipment found in a recording studio commonly includes:

- Mixing console

- Multitrack recorder

- Microphones

- Reference monitors, which are loudspeakers with a flat frequency response

- Keyboard

- Digital audio workstation

- Music workstation

- On Air or Recording Light

- Outboard effects, such as compressors, reverbs, or equalizers

[edit] Digital audio workstations

Main article: Digital audio workstation

General purpose computers have rapidly assumed a large role in the recording process, being able to replace the mixing consoles, recorders, synthesizers, samplers and sound effects devices. A computer thus outfitted is called a Digital Audio Workstation, or DAW. Popular audio-recording software includes FL Studio, Digidesign's Pro Tools—the industry standard for most studios—Cubase and Nuendo both by Steinberg, MOTU Digital Performer—the standard for MIDI. Other software applications include Ableton Live, Cakewalk SONAR, ACID Pro, Apple Logic Studio, Adobe Audition, Audacity, and Ardour.Current software applications are more reliant on the audio recording hardware than the computer they are running on, therefore typical high-end computer hardware is less of a priority. While Apple Macintosh is common for studio work, there is a breadth of software available for Microsoft Windows and Linux. A sizeable portion of both commercial and home studios can be seen running PC-based multitrack audio software.

If no mixing console is used and all mixing is done using only a keyboard and mouse, this is referred to as mixing in the box.

[edit] Project studios

A small, personal recording studio is sometimes called a project studio or home studio. Such studios often cater to specific needs of an individual artist, or are used as a non-commercial hobby. The first modern project studios came into being during the mid 1980s, with the advent of affordable multitrack recorders, synthesizers and microphones. The phenomenon has flourished with falling prices of MIDI equipment and accessories, as well as inexpensive digital hard-disk recording products.Recording drums and electric guitar in a home studio is challenging, because they are usually the loudest instruments. Conventional drums require sound isolation in this scenario, unlike electronic or sampled drums. Getting an authentic electric guitar amp sound including power-tube distortion requires a power attenuator (either power-soak or power-supply based) or an isolation box or booth. A convenient compromise is amp simulation, whether a modelling amp, preamp/processor, or software-based guitar amp simulator. Sometimes, musicians replace loud, inconvenient instruments such as drums, with keyboards, which today often provide somewhat realistic sampling.

[edit] Isolation booth

An isolation booth is a standard small room in a recording studio, which is both soundproofed to keep out external sounds and keep in the internal sounds and, like all the other recording rooms in sound industry, it is designed for having a lesser amount of diffused reflections from walls to make a good sounding room. A drummer, vocalist, or guitar speaker cabinet, along with microphones, is acoustically isolated in the room. A professional recording studio has a control room, a large live room, and one or more small isolation booths. All rooms are soundproofed such as with double-layer walls with dead space and insulation in-between the two walls, forming a room-within-a-room.There are variations of the same concept, including a portable standalone isolation booth, a compact guitar speaker isolation cabinet, or a larger guitar speaker cabinet isolation box.

A gobo panel achieves the same idea to a much more moderate extent; for example, a drum kit that is too loud in the live room or on stage can have acrylic glass see-through gobo panels placed around it to deflect the sound and keep it from bleeding into the other microphones, allowing more independent control of each instrument channel at the mixing board.

All rooms in a recording studio may have a reconfigurable combination of reflective and non-reflective surfaces, to control the amount of reverberation.

[edit] On Air or Recording Light

| This section does not cite any references or sources. Please help improve this article by adding citations to reliable sources. Unsourced material may be challenged and removed. (August 2010) |

The device consists of a light with either On Air or Recording on the front panel and contains an array of complicated electronics to read the recording signal from professional mixing consoles.

[edit] History

[edit] 1890s to 1930s

In the era of acoustical recordings (prior to the introduction of microphones, electrical recording and amplification), the earliest recording studios were very basic facilities, being essentially soundproof rooms that isolated the performers from outside noise. During this era it was not uncommon for recordings to be made in any available location, such as a local ballroom, using portable acoustic recording equipment.In this period, master recordings were made using a direct-to-disc cutting process. Performers were typically grouped around a large acoustic horn (an enlarged version of the familiar phonograph horn). The acoustic energy from the voices and/or instruments was channeled through the horn's diaphragm to a mechanical cutting lathe located in the next room, which inscribed the signal as a modulated groove directly onto the surface of the master cylinder or disc.

Following the invention and commercial introduction of the microphone, the electronic amplifier, the mixing desk and the loudspeaker, the recording industry gradually converted to electric recording, and by 1925 this technology had replaced mechanical acoustic recording methods for such major labels as RCA Victor and Columbia, and by 1933 acoustic recording was completely disused.

[edit] 1940s to 1970s

Electrical recording was common by the early 1930s, and mastering lathes were now electrically powered, but master recordings still had to be cut direct-to-disc. In line with the prevailing musical trends, studios in this period were primarily designed for the live recording of symphony orchestras and other large instrumental ensembles. Engineers soon found that large, reverberant spaces like concert halls created a vibrant acoustic signature that greatly enhanced the sound of the recording, and in this period large, acoustically "live" halls were favored, rather than the acoustically "dead" booths and studio rooms that became common after the 1960s.

Because of the limits of the recording technology, studios of the mid-20th century were designed around the concept of grouping musicians and singers, rather than separating them, and placing the performers and the microphones strategically to capture the complex acoustic and harmonic interplay that emerged during the performance. Modern sound stages still sometimes use this approach for large film scoring projects today.

Because of their superb acoustics, many of the larger studios were converted churches. Examples include George Martin's AIR Studios in London, the famed Columbia Records 30th Street Studio in New York City (a converted Armenian church, with a ceiling over 100 feet high) [1], and the equally famous Decca Records Pythian Temple studio in New York (where artists like Louis Jordan, Bill Haley and Buddy Holly were recorded) which was also a large converted church that featured a high, domed ceiling in the center of the hall.

Facilities like the Columbia Records 30th Street Studio in New York and EMI's Abbey Road Studio in London were renowned for their 'trademark' sound—which was (and still is) easily identifiable by audio professionals—and for the skill of their staff engineers.

In New York City, Columbia Records had some of the most highly respected sound recording studios, including the Columbia 30th Street Studio at 207 East 30th Street, the CBS Studio Building at 49 East 52nd Street, Liederkranz Hall at 111 East 58th Street between Park and Lexington Avenues (a building built by and formerly belonging to a German cultural and musical society, The Liederkranz Club and Society)[2][3], and one of their earliest recording studios, "Studio A" at 799 Seventh Avenue.[1]

Electric recording studios in the mid-20th century often lacked isolation booths, baffles, and sometimes even speakers, and it was not until the 1960s, with the introduction of the high-fidelity headphones that it became common practice for performers to use headsets to monitor their performance during recording and listen to playbacks.

It was difficult to isolate all the performers—a major reason that this practice was not used was simply because recordings were usually made as live ensemble 'takes' and all the performers needed to be able to see each other and the ensemble leader while playing. The recording engineers who trained in this period learned to take advantage of the complex acoustic effects that could be created through "leakage" between different microphones and groups of instruments, and these technicians became extremely skilled at capturing the unique acoustic properties of their studios and the musicians in performance.

The use of different kinds of microphones and their placement around the studio was a crucial part of the recording process, and particular brands of microphone were used by engineers for their specific audio characteristics. The smooth-toned ribbon microphones developed by the RCA company in the 1930s were crucial to the 'crooning' style perfected by Bing Crosby, and the famous Neumann U47 condenser microphone was one of the most widely used from the 1950s. This model is still widely regarded by audio professionals as one of the best microphones of its type ever made.

Learning the correct placement of microphones was a major part of the training of young engineers, and many became extremely skilled in this craft. Well into the 1960s, in the classical field it was not uncommon for engineers to make high-quality orchestral recordings using only one or two microphones suspended above the orchestra.

In the 1960s, engineers began experimenting with placing microphones much closer to instruments than had previously been the norm. The distinctive rasping tone of the horn sections on the Beatles recordings "Good Morning Good Morning" and "Lady Madonna" were achieved by having the saxophone players position their instruments so that microphones were virtually inside the mouth of the horn.

The unique sonic characteristics of the major studios imparted a special character to many of the most famous popular recordings of the 1950s and 1960s, and the recording companies jealously guarded these facilities. According to sound historian David Simons, after Columbia took over the 30th Street Studios in the late 1940s and A&R manager Mitch Miller had tweaked it to perfection, Miller issued a standing order that the drapes and other fittings were not to be touched, and the cleaners had specific orders never to mop the bare wooden floor for fear it might alter the acoustic properties of the hall.

There were several other features of studios in this period that contributed to their unique "sonic signatures". As well as the inherent sound of the large recording rooms, many of the best studios incorporated specially-designed echo chambers, purpose-built rooms which were often built beneath the main studio.

These were typically long, low rectangular spaces constructed from hard, sound-reflective materials like concrete, fitted with a loudspeaker at one end and one or more microphones at the other. During a recording session, a signal from one or more of the microphones in the studio could be routed to the loudspeaker in the echo chamber; the sound from the speaker reverberated through the chamber and the enhanced signal was picked up by the microphone at the other end. This echo-enhanced signal—which was often used to 'sweeten' the sound of vocals—could then be blended in with the primary signal from the microphone in the studio and mixed into the track as the master recording was being made.

Special equipment was another notable feature of the "classic" recording studio. The biggest studios were owned and operated by large media companies like RCA, Columbia and EMI, who typically had their own electronics research and development divisions that designed and built custom-made recording equipment and mixing consoles for their studios.

Likewise, the smaller independent studios were often owned by skilled electronics engineers who designed and built their own desks and other equipment. A good example of this is the famous Gold Star Studios in Los Angeles, the site of many famous American pop recordings of the 1960s. Co-owner David S. Gold built the studio's main mixing desk and many additional pieces of equipment and he also designed the studio's unique trapezoidal echo chambers.

During the 1950s and 1960s the sound of pop recordings was further defined by the introduction of proprietary sound processing devices such as equalizers and compressors, which were manufactured by specialist electronics companies. One of the best known of these was the famous Pultec equalizer, which was used by almost all the major commercial studios of the time.

With the introduction of multi-track recording, it became possible to record instruments and singers separately and at different times on different tracks on tape, although it was not until the 1970s that the large recording companies began to adopt this practice widely, and throughout the Sixties many "pop" classics were still recorded live in a single take.

After the Sixties the emphasis shifted to isolation and sound-proofing, with treatments like echo and reverberation added separately during the mixing process, rather than being blended in during the recording. One regrettable outcome of this trend, which coincided with rising inner-city property values, was that many of the largest studios were either demolished or redeveloped for other uses.

In the mid 20th century, recordings were analog, made on ¼-inch or ½-inch magnetic tape, with multitrack recording reaching 8 tracks in the 1950s, 16 in 1968, and 32 in the 1970s. The commonest such tape is the 2-inch analog, capable of containing up to 24 individual tracks. Generally, after an audio mix is set up on a 24-track tape machine, the signal is played back and sent to a different machine, which records the combined signals (called printing) to a ½-inch 2-track stereo tape, called a master.

Before digital recording, the total number of available tracks onto which one could record was measured in multiples of 24, based on the number of 24-track tape machines being used. Most recording studios now use digital recording equipment, which limits the number of available tracks only on the basis of the mixing console's or computer hardware interface's capacity and the ability of the hardware to cope with processing demands.

Analog tape machines are still well sought, for some purists label digitally recorded audio as sounding too harsh, and the scarcity and age of analog tape machines greatly increases their value, as does the fact that many audio engineers still insist on recording only to analog tape. This harshness is incorrectly attributed by some of them[who?] to the belief that digital recording will sample a sound wave many times per second allowing an illusion of solid sound waves to be created, where in contrast analog tape captures a sound wave in its entirety.

However, others[who?] simply argue that the lack of high frequency noise and the higher fidelity of the digital medium make the recorded higher frequencies more prominent, which results in such perceived harshness in contrast to analog recording. Still others[who?] point to problems of early digital recordings caused by the inexperience of sound engineers with the new medium as the cause for critics to the digital systems. Finally, another possibly relevant effect derives from the fact that, since CD-quality audio uses a sampling rate of 44.1 kHz, no frequencies above the Nyquist frequency of 22050 Hz are acceptable for recording (otherwise, aliasing occurs). Because of that, very steep low-pass filters are used on frequencies above 20 kHz (the theoretical limit of human hearing) that may introduce slight distortions into the audible-range signal. This is one of the several reasons for the push on high-end equipment towards higher sampling rates, such as 48 kHz (used in video production), 88.2 kHz, 96 kHz and even 192 kHz.

[edit] Radio studios

Radio studios are very similar to recording studios, particularly in the case of production studios which are not normally used on-air. This type of studio would normally have all of the same equipment that any other audio recording studio would have, particularly if it is at a large station, or at a combined facility that houses a station group.Broadcast studios also use many of the same principles such as sound isolation, with adaptations suited to the live on-air nature of their use. Such equipment would commonly include a telephone hybrid for putting telephone calls on the air, a POTS codec for receiving remote broadcasts, a dead air alarm for detecting unexpected silence, and a broadcast delay for dropping anything from coughs to profanity. In the U.S., stations licensed by the Federal Communications Commission (FCC) also must have an Emergency Alert System decoder (typically in the studio), and in the case of full-power stations, an encoder that can interrupt programming on all channels which a station transmits in order to broadcast urgent warnings.

Computers are also used for playing ads, jingles, bumpers, soundbites, phone calls, sound effects, traffic and weather reports, and now full broadcast automation when nobody is around. For talk shows, a producer and/or assistant in a control room runs the show, including screening calls and entering the callers' names and subject into a queue, which the show's host can see and make a proper introduction with. Radio contest winners can also be edited on the fly and put on the air within a minute or two after they have been recorded accepting their prize.

Additionally, digital mixing consoles can be interconnected via audio over Ethernet, or split into two parts, with inputs and outputs wired to a rackmount audio engine, and one or more control surfaces (mixing boards) and/or computers connected via serial port, allowing the producer or the talent to control the show from either point. With Ethernet and audio over IP (live) or FTP (recorded), this also allows remote access, so that DJs can do shows from a home studio via ISDN or the Internet. Additional outside audio connections are required for the studio/transmitter link for over-the-air stations, satellite dishes for sending and receiving shows, and for webcasting or podcasting.

- Audio engineering

- Isolation cabinet (guitar)

- Re-amp

- Room acoustics

- Sound recording

- Soundproofing

- Sound baffle

Most microphones today use electromagnetic induction (dynamic microphone), capacitance change (condenser microphone), piezoelectric generation, or light modulation to produce an electrical voltage signal from mechanical vibration.

[edit] Components

The sensitive transducer element of a microphone is called its element or capsule. A complete microphone also includes a housing, some means of bringing the signal from the element to other equipment, and often an electronic circuit to adapt the output of the capsule to the equipment being driven. A wireless microphone contains a radio transmitter.[edit] Varieties

Microphones are referred to by their transducer principle, such as condenser, dynamic, etc., and by their directional characteristics. Sometimes other characteristics such as diaphragm size, intended use or orientation of the principal sound input to the principal axis (end- or side-address) of the microphone are used to describe the microphone.[edit] Condenser microphone

The condenser microphone, invented at Bell Labs in 1916 by E. C. Wente[2] is also called a capacitor microphone or electrostatic microphone. Here, the diaphragm acts as one plate of a capacitor, and the vibrations produce changes in the distance between the plates. There are two types, depending on the method of extracting the audio signal from the transducer: DC-biased and radio frequency (RF) or high frequency (HF) condenser microphones. With a DC-biased microphone, the plates are biased with a fixed charge (Q). The voltage maintained across the capacitor plates changes with the vibrations in the air, according to the capacitance equation (C = Q / V), where Q = charge in coulombs, C = capacitance in farads and V = potential difference in volts. The capacitance of the plates is inversely proportional to the distance between them for a parallel-plate capacitor. (See capacitance for details.) The assembly of fixed and movable plates is called an "element" or "capsule."A nearly constant charge is maintained on the capacitor. As the capacitance changes, the charge across the capacitor does change very slightly, but at audible frequencies it is sensibly constant. The capacitance of the capsule (around 5 to 100 pF) and the value of the bias resistor (100 megohms to tens of gigohms) form a filter that is high-pass for the audio signal, and low-pass for the bias voltage. Note that the time constant of an RC circuit equals the product of the resistance and capacitance.

Within the time-frame of the capacitance change (as much as 50 ms at 20 Hz audio signal), the charge is practically constant and the voltage across the capacitor changes instantaneously to reflect the change in capacitance. The voltage across the capacitor varies above and below the bias voltage. The voltage difference between the bias and the capacitor is seen across the series resistor. The voltage across the resistor is amplified for performance or recording.

RF condenser microphones use a comparatively low RF voltage, generated by a low-noise oscillator. The oscillator may either be amplitude modulated by the capacitance changes produced by the sound waves moving the capsule diaphragm, or the capsule may be part of a resonant circuit that modulates the frequency of the oscillator signal. Demodulation yields a low-noise audio frequency signal with a very low source impedance. The absence of a high bias voltage permits the use of a diaphragm with looser tension, which may be used to achieve wider frequency response due to higher compliance. The RF biasing process results in a lower electrical impedance capsule, a useful by-product of which is that RF condenser microphones can be operated in damp weather conditions that could create problems in DC-biased microphones with contaminated insulating surfaces. The Sennheiser "MKH" series of microphones use the RF biasing technique.

Condenser microphones span the range from telephone transmitters through inexpensive karaoke microphones to high-fidelity recording microphones. They generally produce a high-quality audio signal and are now the popular choice in laboratory and studio recording applications. The inherent suitability of this technology is due to the very small mass that must be moved by the incident sound wave, unlike other microphone types that require the sound wave to do more work. They require a power source, provided either via microphone outputs as phantom power or from a small battery. Power is necessary for establishing the capacitor plate voltage, and is also needed to power the microphone electronics (impedance conversion in the case of electret and DC-polarized microphones, demodulation or detection in the case of RF/HF microphones). Condenser microphones are also available with two diaphragms that can be electrically connected to provide a range of polar patterns (see below), such as cardioid, omnidirectional, and figure-eight. It is also possible to vary the pattern continuously with some microphones, for example the Røde NT2000 or CAD M179.

[edit] Electret condenser microphone

Main article: Electret microphone

An electret microphone is a relatively new type of capacitor microphone invented at Bell laboratories in 1962 by Gerhard Sessler and Jim West.[3] The externally applied charge described above under condenser microphones is replaced by a permanent charge in an electret material. An electret is a ferroelectric material that has been permanently electrically charged or polarized. The name comes from electrostatic and magnet; a static charge is embedded in an electret by alignment of the static charges in the material, much the way a magnet is made by aligning the magnetic domains in a piece of iron.Due to their good performance and ease of manufacture, hence low cost, the vast majority of microphones made today are electret microphones; a semiconductor manufacturer[4] estimates annual production at over one billion units. Nearly all cell-phone, computer, PDA and headset microphones are electret types. They are used in many applications, from high-quality recording and lavalier use to built-in microphones in small sound recording devices and telephones. Though electret microphones were once considered low quality, the best ones can now rival traditional condenser microphones in every respect and can even offer the long-term stability and ultra-flat response needed for a measurement microphone. Unlike other capacitor microphones, they require no polarizing voltage, but often contain an integrated preamplifier that does require power (often incorrectly called polarizing power or bias). This preamplifier is frequently phantom powered in sound reinforcement and studio applications. Microphones designed for personal computer (PC) use, sometimes called multimedia microphones, use a stereo 3.5 mm plug (though a mono source) with the ring receiving power via a resistor from (normally) a 5 V supply in the computer; unfortunately, a number of incompatible dynamic microphones are fitted with 3.5 mm plugs too. While few electret microphones rival the best DC-polarized units in terms of noise level, this is not due to any inherent limitation of the electret. Rather, mass production techniques needed to produce microphones cheaply don't lend themselves to the precision needed to produce the highest quality microphones, due to the tight tolerances required in internal dimensions. These tolerances are the same for all condenser microphones, whether the DC, RF or electret technology is used.

[edit] Dynamic microphone

Dynamic microphones work via electromagnetic induction. They are robust, relatively inexpensive and resistant to moisture. This, coupled with their potentially high gain before feedback makes them ideal for on-stage use.

Moving-coil microphones use the same dynamic principle as in a loudspeaker, only reversed. A small movable induction coil, positioned in the magnetic field of a permanent magnet, is attached to the diaphragm. When sound enters through the windscreen of the microphone, the sound wave moves the diaphragm. When the diaphragm vibrates, the coil moves in the magnetic field, producing a varying current in the coil through electromagnetic induction. A single dynamic membrane does not respond linearly to all audio frequencies. Some microphones for this reason utilize multiple membranes for the different parts of the audio spectrum and then combine the resulting signals. Combining the multiple signals correctly is difficult and designs that do this are rare and tend to be expensive. There are on the other hand several designs that are more specifically aimed towards isolated parts of the audio spectrum. The AKG D 112, for example, is designed for bass response rather than treble.[5] In audio engineering several kinds of microphones are often used at the same time to get the best result.

[edit] Ribbon microphone

Main article: Ribbon microphone

Ribbon microphones use a thin, usually corrugated metal ribbon suspended in a magnetic field. The ribbon is electrically connected to the microphone's output, and its vibration within the magnetic field generates the electrical signal. Ribbon microphones are similar to moving coil microphones in the sense that both produce sound by means of magnetic induction. Basic ribbon microphones detect sound in a bi-directional (also called figure-eight) pattern because the ribbon, which is open to sound both front and back, responds to the pressure gradient rather than the sound pressure. Though the symmetrical front and rear pickup can be a nuisance in normal stereo recording, the high side rejection can be used to advantage by positioning a ribbon microphone horizontally, for example above cymbals, so that the rear lobe picks up only sound from the cymbals. Crossed figure 8, or Blumlein pair, stereo recording is gaining in popularity, and the figure 8 response of a ribbon microphone is ideal for that application.

Other directional patterns are produced by enclosing one side of the ribbon in an acoustic trap or baffle, allowing sound to reach only one side. The classic RCA Type 77-DX microphone has several externally adjustable positions of the internal baffle, allowing the selection of several response patterns ranging from "Figure-8" to "Unidirectional". Such older ribbon microphones, some of which still provide high quality sound reproduction, were once valued for this reason, but a good low-frequency response could only be obtained when the ribbon was suspended very loosely, which made them relatively fragile. Modern ribbon materials, including new nanomaterials[6] have now been introduced that eliminate those concerns, and even improve the effective dynamic range of ribbon microphones at low frequencies. Protective wind screens can reduce the danger of damaging a vintage ribbon, and also reduce plosive artifacts in the recording. Properly designed wind screens produce negligible treble attenuation. In common with other classes of dynamic microphone, ribbon microphones don't require phantom power; in fact, this voltage can damage some older ribbon microphones. Some new modern ribbon microphone designs incorporate a preamplifier and, therefore, do require phantom power, and circuits of modern passive ribbon microphones, i.e., those without the aforementioned preamplifier, are specifically designed to resist damage to the ribbon and transformer by phantom power. Also there are new ribbon materials available that are immune to wind blasts and phantom power.

[edit] Carbon microphone

Main article: Carbon microphone

A carbon microphone, also known as a carbon button microphone (or sometimes just a button microphone), use a capsule or button containing carbon granules pressed between two metal plates like the Berliner and Edison microphones. A voltage is applied across the metal plates, causing a small current to flow through the carbon. One of the plates, the diaphragm, vibrates in sympathy with incident sound waves, applying a varying pressure to the carbon. The changing pressure deforms the granules, causing the contact area between each pair of adjacent granules to change, and this causes the electrical resistance of the mass of granules to change. The changes in resistance cause a corresponding change in the current flowing through the microphone, producing the electrical signal. Carbon microphones were once commonly used in telephones; they have extremely low-quality sound reproduction and a very limited frequency response range, but are very robust devices. The Boudet microphone, which used relatively large carbon balls, was similar to the granule carbon button microphones.[7]Unlike other microphone types, the carbon microphone can also be used as a type of amplifier, using a small amount of sound energy to control a larger amount of electrical energy. Carbon microphones found use as early telephone repeaters, making long distance phone calls possible in the era before vacuum tubes. These repeaters worked by mechanically coupling a magnetic telephone receiver to a carbon microphone: the faint signal from the receiver was transferred to the microphone, with a resulting stronger electrical signal to send down the line. One illustration of this amplifier effect was the oscillation caused by feedback, resulting in an audible squeal from the old "candlestick" telephone if its earphone was placed near the carbon microphone.

[edit] Piezoelectric microphone

A crystal microphone or piezo microphone uses the phenomenon of piezoelectricity — the ability of some materials to produce a voltage when subjected to pressure — to convert vibrations into an electrical signal. An example of this is potassium sodium tartrate, which is a piezoelectric crystal that works as a transducer, both as a microphone and as a slimline loudspeaker component. Crystal microphones were once commonly supplied with vacuum tube (valve) equipment, such as domestic tape recorders. Their high output impedance matched the high input impedance (typically about 10 megohms) of the vacuum tube input stage well. They were difficult to match to early transistor equipment, and were quickly supplanted by dynamic microphones for a time, and later small electret condenser devices. The high impedance of the crystal microphone made it very susceptible to handling noise, both from the microphone itself and from the connecting cable.Piezoelectric transducers are often used as contact microphones to amplify sound from acoustic musical instruments, to sense drum hits, for triggering electronic samples, and to record sound in challenging environments, such as underwater under high pressure. Saddle-mounted pickups on acoustic guitars are generally piezoelectric devices that contact the strings passing over the saddle. This type of microphone is different from magnetic coil pickups commonly visible on typical electric guitars, which use magnetic induction, rather than mechanical coupling, to pick up vibration.

[edit] Fiber optic microphone

A fiber optic microphone converts acoustic waves into electrical signals by sensing changes in light intensity, instead of sensing changes in capacitance or magnetic fields as with conventional microphones.[8][9]

During operation, light from a laser source travels through an optical fiber to illuminate the surface of a tiny, sound-sensitive reflective diaphragm. Sound causes the diaphragm to vibrate, thereby minutely changing the intensity of the light it reflects. The modulated light is then transmitted over a second optical fiber to a photo detector, which transforms the intensity-modulated light into analog or digital audio for transmission or recording. Fiber optic microphones possess high dynamic and frequency range, similar to the best high fidelity conventional microphones.

Fiber optic microphones do not react to or influence any electrical, magnetic, electrostatic or radioactive fields (this is called EMI/RFI immunity). The fiber optic microphone design is therefore ideal for use in areas where conventional microphones are ineffective or dangerous, such as inside industrial turbines or in magnetic resonance imaging (MRI) equipment environments.

Fiber optic microphones are robust, resistant to environmental changes in heat and moisture, and can be produced for any directionality or impedance matching. The distance between the microphone's light source and its photo detector may be up to several kilometers without need for any preamplifier and/or other electrical device, making fiber optic microphones suitable for industrial and surveillance acoustic monitoring.

Fiber optic microphones are used in very specific application areas such as for infrasound monitoring and noise-canceling. They have proven especially useful in medical applications, such as allowing radiologists, staff and patients within the powerful and noisy magnetic field to converse normally, inside the MRI suites as well as in remote control rooms.[10]) Other uses include industrial equipment monitoring and sensing, audio calibration and measurement, high-fidelity recording and law enforcement.

[edit] Laser microphone

Main article: Laser microphone

Laser microphones are often portrayed in movies as spy gadgets. A laser beam is aimed at the surface of a window or other plane surface that is affected by sound. The slight vibrations of this surface displace the returned beam, causing it to trace the sound wave. The vibrating laser spot is then converted back to sound. In a more robust and expensive implementation, the returned light is split and fed to an interferometer, which detects movement of the surface. The former implementation is a tabletop experiment; the latter requires an extremely stable laser and precise optics.A new type of laser microphone is a device that uses a laser beam and smoke or vapor to detect sound vibrations in free air. On 25 August 2009, U.S. patent 7,580,533 issued for a Particulate Flow Detection Microphone based on a laser-photocell pair with a moving stream of smoke or vapor in the laser beam's path. Sound pressure waves cause disturbances in the smoke that in turn cause variations in the amount of laser light reaching the photo detector. A prototype of the device was demonstrated at the 127th Audio Engineering Society convention in New York City from 9 through 12 October 2009.

[edit] Liquid microphone

Main article: Water microphone

Early microphones did not produce intelligible speech, until Alexander Graham Bell made improvements including a variable resistance microphone/transmitter. Bell's liquid transmitter consisted of a metal cup filled with water with a small amount of sulfuric acid added. A sound wave caused the diaphragm to move, forcing a needle to move up and down in the water. The electrical resistance between the wire and the cup was then inversely proportional to the size of the water meniscus around the submerged needle. Elisha Gray filed a caveat for a version using a brass rod instead of the needle. Other minor variations and improvements were made to the liquid microphone by Majoranna, Chambers, Vanni, Sykes, and Elisha Gray, and one version was patented by Reginald Fessenden in 1903. These were the first working microphones, but they were not practical for commercial application. The famous first phone conversation between Bell and Watson took place using a liquid microphone.[edit] MEMS microphone

Main article: Microelectromechanical systems

The MEMS (MicroElectrical-Mechanical System) microphone is also called a microphone chip or silicon microphone. The pressure-sensitive diaphragm is etched directly into a silicon chip by MEMS techniques, and is usually accompanied with integrated preamplifier. Most MEMS microphones are variants of the condenser microphone design. Often MEMS microphones have built in analog-to-digital converter (ADC) circuits on the same CMOS chip making the chip a digital microphone and so more readily integrated with modern digital products. Major manufacturers producing MEMS silicon microphones are Wolfson Microelectronics (WM7xxx), Analog Devices, Akustica (AKU200x), Infineon (SMM310 product), Knowles Electronics, Memstech (MSMx), NXP Semiconductors, Sonion MEMS, AAC Acoustic Technologies,[11] and Omron.[12][edit] Speakers as microphones

A loudspeaker, a transducer that turns an electrical signal into sound waves, is the functional opposite of a microphone. Since a conventional speaker is constructed much like a dynamic microphone (with a diaphragm, coil and magnet), speakers can actually work "in reverse" as microphones. The result, though, is a microphone with poor quality, limited frequency response (particularly at the high end), and poor sensitivity. In practical use, speakers are sometimes used as microphones in applications where high quality and sensitivity are not needed such as intercoms, walkie-talkies or Video game voice chat peripherals, or when conventional microphones are in short supply.However, there is at least one other practical application of this principle: Using a medium-size woofer placed closely in front of a "kick" (bass drum) in a drum set to act as a microphone. The use of relatively large speakers to transduce low frequency sound sources, especially in music production, is becoming fairly common. A product example of this type of device is the Yamaha Subkick, a 6.5-inch (170 mm) woofer shock-mounted it into a 10" drum shell used in front of kick drums. Since a relatively massive membrane is unable to transduce high frequencies, placing a speaker in front of a kick drum is often ideal for reducing cymbal and snare bleed into the kick drum sound. Less commonly, microphones themselves can be used as speakers, almost always as tweeters. Microphones, however, are not designed to handle the power that speaker components are routinely required to cope with. One instance of such an application was the STC microphone-derived 4001 super-tweeter, which was successfully used in a number of high quality loudspeaker systems from the late 1960s to the mid-70s.

[edit] Capsule design and directivity

The inner elements of a microphone are the primary source of differences in directivity. A pressure microphone uses a diaphragm between a fixed internal volume of air and the environment, and responds uniformly to pressure from all directions, so it is said to be omnidirectional. A pressure-gradient microphone uses a diaphragm that is at least partially open on both sides. The pressure difference between the two sides produces its directional characteristics. Other elements such as the external shape of the microphone and external devices such as interference tubes can also alter a microphone's directional response. A pure pressure-gradient microphone is equally sensitive to sounds arriving from front or back, but insensitive to sounds arriving from the side because sound arriving at the front and back at the same time creates no gradient between the two. The characteristic directional pattern of a pure pressure-gradient microphone is like a figure-8. Other polar patterns are derived by creating a capsule that combines these two effects in different ways. The cardioid, for instance, features a partially closed backside, so its response is a combination of pressure and pressure-gradient characteristics.[13][edit] Microphone polar patterns

(Microphone facing top of page in diagram, parallel to page):Some microphone designs combine several principles in creating the desired polar pattern. This ranges from shielding (meaning diffraction/dissipation/absorption) by the housing itself to electronically combining dual membranes.

[edit] Omnidirectional

An omnidirectional (or nondirectional) microphone's response is generally considered to be a perfect sphere in three dimensions. In the real world, this is not the case. As with directional microphones, the polar pattern for an "omnidirectional" microphone is a function of frequency. The body of the microphone is not infinitely small and, as a consequence, it tends to get in its own way with respect to sounds arriving from the rear, causing a slight flattening of the polar response. This flattening increases as the diameter of the microphone (assuming it's cylindrical) reaches the wavelength of the frequency in question. Therefore, the smallest diameter microphone gives the best omnidirectional characteristics at high frequencies.The wavelength of sound at 10 kHz is little over an inch (3.4 cm) so the smallest measuring microphones are often 1/4" (6 mm) in diameter, which practically eliminates directionality even up to the highest frequencies. Omnidirectional microphones, unlike cardioids, do not employ resonant cavities as delays, and so can be considered the "purest" microphones in terms of low coloration; they add very little to the original sound. Being pressure-sensitive they can also have a very flat low-frequency response down to 20 Hz or below. Pressure-sensitive microphones also respond much less to wind noise and plosives than directional (velocity sensitive) microphones.

An example of a nondirectional microphone is the round black eight ball.[14]

[edit] Unidirectional

A unidirectional microphone is sensitive to sounds from only one direction. The diagram above illustrates a number of these patterns. The microphone faces upwards in each diagram. The sound intensity for a particular frequency is plotted for angles radially from 0 to 360°. (Professional diagrams show these scales and include multiple plots at different frequencies. The diagrams given here provide only an overview of typical pattern shapes, and their names.)[edit] Cardioids

The most common unidirectional microphone is a cardioid microphone, so named because the sensitivity pattern is heart-shaped. A hyper-cardioid microphone is similar but with a tighter area of front sensitivity and a smaller lobe of rear sensitivity. A super-cardioid microphone is similar to a hyper-cardioid, except there is more front pickup and less rear pickup. These three patterns are commonly used as vocal or speech microphones, since they are good at rejecting sounds from other directions.A cardioid microphone is effectively a superposition of an omnidirectional and a figure-8 microphone; for sound waves coming from the back, the negative signal from the figure-8 cancels the positive signal from the omnidirectional element, whereas for sound waves coming from the front, the two add to each other. A hypercardioid microphone is similar, but with a slightly larger figure-8 contribution. Since pressure gradient transducer microphones are directional, putting them very close to the sound source (at distances of a few centimeters) results in a bass boost. This is known as the proximity effect.[15]

[edit] Bi-directional

"Figure 8" or bi-directional microphones receive sound from both the front and back of the element. Most ribbon microphones are of this pattern.[edit] Shotgun

Shotgun microphones are the most highly directional. They have small lobes of sensitivity to the left, right, and rear but are significantly less sensitive to the side and rear than other directional microphones. This results from placing the element at the end of a tube with slots cut along the side; wave cancellation eliminates much of the off-axis sound. Due to the narrowness of their sensitivity area, shotgun microphones are commonly used on television and film sets, in stadiums, and for field recording of wildlife.[edit] Boundary or "PZM"

Several approaches have been developed for effectively using a microphone in less-than-ideal acoustic spaces, which often suffer from excessive reflections from one or more of the surfaces (boundaries) that make up the space. If the microphone is placed in, or very close to, one of these boundaries, the reflections from that surface are not sensed by the microphone. Initially this was done by placing an ordinary microphone adjacent to the surface, sometimes in a block of acoustically transparent foam. Sound engineers Ed Long and Ron Wickersham developed the concept of placing the diaphgram parallel to and facing the boundary.[16] While the patent has expired, "Pressure Zone Microphone" and "PZM" are still active trademarks of Crown International, and the generic term "boundary microphone" is preferred. While a boundary microphone was initially implemented using an omnidirectional element, it is also possible to mount a directional microphone close enough to the surface to gain some of the benefits of this technique while retaining the directional properties of the element. Crown's trademark on this approach is "Phase Coherent Cardioid" or "PCC," but there are other makers who employ this technique as well.[edit] Application-specific designs

A lavalier microphone is made for hands-free operation. These small microphones are worn on the body. Originally, they were held in place with a lanyard worn around the neck, but more often they are fastened to clothing with a clip, pin, tape or magnet. The lavalier cord may be hidden by clothes and either run to an RF transmitter in a pocket or clipped to a belt (for mobile use), or run directly to the mixer (for stationary applications).A wireless microphone transmits the audio as a radio or optical signal rather than via a cable. It usually sends its signal using a small FM radio transmitter to a nearby receiver connected to the sound system, but it can also use infrared waves if the transmitter and receiver are within sight of each other.

A contact microphone picks up vibrations directly from a solid surface or object, as opposed to sound vibrations carried through air. One use for this is to detect sounds of a very low level, such as those from small objects or insects. The microphone commonly consists of a magnetic (moving coil) transducer, contact plate and contact pin. The contact plate is placed directly on the vibrating part of a musical instrument or other surface, and the contact pin transfers vibrations to the coil. Contact microphones have been used to pick up the sound of a snail's heartbeat and the footsteps of ants. A portable version of this microphone has recently been developed. A throat microphone is a variant of the contact microphone that picks up speech directly from a person's throat, which it is strapped to. This lets the device be used in areas with ambient sounds that would otherwise make the speaker inaudible.

A parabolic microphone uses a parabolic reflector to collect and focus sound waves onto a microphone receiver, in much the same way that a parabolic antenna (e.g. satellite dish) does with radio waves. Typical uses of this microphone, which has unusually focused front sensitivity and can pick up sounds from many meters away, include nature recording, outdoor sporting events, eavesdropping, law enforcement, and even espionage. Parabolic microphones are not typically used for standard recording applications, because they tend to have poor low-frequency response as a side effect of their design.

A stereo microphone integrates two microphones in one unit to produce a stereophonic signal. A stereo microphone is often used for broadcast applications or field recording where it would be impractical to configure two separate condenser microphones in a classic X-Y configuration (see microphone practice) for stereophonic recording. Some such microphones have an adjustable angle of coverage between the two channels.

A noise-canceling microphone is a highly directional design intended for noisy environments. One such use is in aircraft cockpits where they are normally installed as boom microphones on headsets. Another use is on loud concert stages for vocalists. Many noise-canceling microphones combine signals received from two diaphragms that are in opposite electrical polarity or are processed electronically. In dual diaphragm designs, the main diaphragm is mounted closest to the intended source and the second is positioned farther away from the source so that it can pick up environmental sounds to be subtracted from the main diaphragm's signal. After the two signals have been combined, sounds other than the intended source are greatly reduced, substantially increasing intelligibility. Other noise-canceling designs use one diaphragm that is affected by ports open to the sides and rear of the microphone, with the sum being a 16 dB rejection of sounds that are farther away. One noise-canceling headset design using a single diaphragm has been used prominently by vocal artists such as Garth Brooks and Janet Jackson.[17] A few noise-canceling microphones are throat microphones.

[edit] Connectors

The most common connectors used by microphones are:

- Male XLR connector on professional microphones

- ¼ inch (sometimes referred to as 6.5 mm) jack plug also known as 1/4 inch TRS connector on less expensive consumer microphones. Many consumer microphones use an unbalanced 1/4 inch phone jack. Harmonica microphones commonly use a high impedance 1/4 inch TS connection to be run through guitar amplifiers.

- 3.5 mm (sometimes referred to as 1/8 inch mini) stereo (wired as mono) mini phone plug on very inexpensive and computer microphones

[edit] Impedance-matching

Microphones have an electrical characteristic called impedance, measured in ohms (Ω), that depends on the design. Typically, the rated impedance is stated.[18] Low impedance is considered under 600 Ω. Medium impedance is considered between 600 Ω and 10 kΩ. High impedance is above 10 kΩ. Owing to their built-in amplifier, condenser microphones typically have an output impedance between 50 and 200 Ω.[19]The output of a given microphone delivers the same power whether it is low or high impedance. If a microphone is made in high and low impedance versions, the high impedance version has a higher output voltage for a given sound pressure input, and is suitable for use with vacuum-tube guitar amplifiers, for instance, which have a high input impedance and require a relatively high signal input voltage to overcome the tubes' inherent noise. Most professional microphones are low impedance, about 200 Ω or lower. Professional vacuum-tube sound equipment incorporates a transformer that steps up the impedance of the microphone circuit to the high impedance and voltage needed to drive the input tube; the impedance conversion inherently creates voltage gain as well. External matching transformers are also available that can be used in-line between a low impedance microphone and a high impedance input.

Low-impedance microphones are preferred over high impedance for two reasons: one is that using a high-impedance microphone with a long cable results in high frequency signal loss due to cable capacitance, which forms a low-pass filter with the microphone output impedance. The other is that long high-impedance cables tend to pick up more hum (and possibly radio-frequency interference (RFI) as well). Nothing is damaged if the impedance between microphone and other equipment is mismatched; the worst that happens is a reduction in signal or change in frequency response.

Most microphones are designed not to have their impedance matched by the load they are connected to.[20] Doing so can alter their frequency response and cause distortion, especially at high sound pressure levels. Certain ribbon and dynamic microphones are exceptions, due to the designers' assumption of a certain load impedance being part of the internal electro-acoustical damping circuit of the microphone.[21][dubious ]

[edit] Digital microphone interface

The AES 42 standard, published by the Audio Engineering Society, defines a digital interface for microphones. Microphones conforming to this standard directly output a digital audio stream through an XLR male connector, rather than producing an analog output. Digital microphones may be used either with new equipment with appropriate input connections that conform to the AES 42 standard, or else via a suitable interface box. Studio-quality microphones that operate in accordance with the AES 42 standard are now available from a number of microphone manufacturers.[edit] Measurements and specifications

Because of differences in their construction, microphones have their own characteristic responses to sound. This difference in response produces non-uniform phase and frequency responses. In addition, microphones are not uniformly sensitive to sound pressure, and can accept differing levels without distorting. Although for scientific applications microphones with a more uniform response are desirable, this is often not the case for music recording, as the non-uniform response of a microphone can produce a desirable coloration of the sound. There is an international standard for microphone specifications,[18] but few manufacturers adhere to it. As a result, comparison of published data from different manufacturers is difficult because different measurement techniques are used. The Microphone Data Website has collated the technical specifications complete with pictures, response curves and technical data from the microphone manufacturers for every currently listed microphone, and even a few obsolete models, and shows the data for them all in one common format for ease of comparison.[1]. Caution should be used in drawing any solid conclusions from this or any other published data, however, unless it is known that the manufacturer has supplied specifications in accordance with IEC 60268-4.

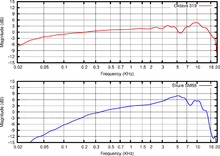

A frequency response diagram plots the microphone sensitivity in decibels over a range of frequencies (typically at least 0–20 kHz), generally for perfectly on-axis sound (sound arriving at 0° to the capsule). Frequency response may be less informatively stated textually like so: "30 Hz–16 kHz ±3 dB". This is interpreted as meaning a nearly flat, linear, plot between the stated frequencies, with variations in amplitude of no more than plus or minus 3 dB. However, one cannot determine from this information how smooth the variations are, nor in what parts of the spectrum they occur. Note that commonly made statements such as "20 Hz–20 kHz" are meaningless without a decibel measure of tolerance. Directional microphones' frequency response varies greatly with distance from the sound source, and with the geometry of the sound source. IEC 60268-4 specifies that frequency response should be measured in plane progressive wave conditions (very far away from the source) but this is seldom practical. Close talking microphones may be measured with different sound sources and distances, but there is no standard and therefore no way to compare data from different models unless the measurement technique is described.

The self-noise or equivalent noise level is the sound level that creates the same output voltage as the microphone does in the absence of sound. This represents the lowest point of the microphone's dynamic range, and is particularly important should you wish to record sounds that are quiet. The measure is often stated in dB(A), which is the equivalent loudness of the noise on a decibel scale frequency-weighted for how the ear hears, for example: "15 dBA SPL" (SPL means sound pressure level relative to 20 micropascals). The lower the number the better. Some microphone manufacturers state the noise level using ITU-R 468 noise weighting, which more accurately represents the way we hear noise, but gives a figure some 11–14 dB higher. A quiet microphone typically measures 20 dBA SPL or 32 dB SPL 468-weighted. Very quiet microphones have existed for years for special applications, such the Brüel & Kjaer 4179, with a noise level around 0 dB SPL. Recently some microphones with low noise specifications have been introduced in the studio/entertainment market, such as models from Neumann and Røde that advertise noise levels between 5–7 dBA. Typically this is achieved by altering the frequency response of the capsule and electronics to result in lower noise within the A-weighting curve while broadband noise may be increased.

The maximum SPL (sound pressure level) the microphone can accept is measured for particular values of total harmonic distortion (THD), typically 0.5%. This amount of distortion is generally inaudible, so one can safely use the microphone at this SPL without harming the recording. Example: "142 dB SPL peak (at 0.5% THD)". The higher the value, the better, although microphones with a very high maximum SPL also have a higher self-noise.

The clipping level is perhaps a better indicator of maximum usable level,[citation needed] as the 1% THD figure usually quoted under max SPL is really a very mild level of distortion, quite inaudible especially on brief high peaks. Harmonic distortion from microphones is usually of low-order (mostly third harmonic) type, and hence not very audible even at 3–5%.[citation needed] Clipping, on the other hand produces a harsh sound on peaks, and should be avoided if at all possible.[citation needed] For some microphones the clipping level may be much higher than the max SPL.

The dynamic range of a microphone is the difference in SPL between the noise floor and the maximum SPL. If stated on its own, for example "120 dB", it conveys significantly less information than having the self-noise and maximum SPL figures individually.

Sensitivity indicates how well the microphone converts acoustic pressure to output voltage. A high sensitivity microphone creates more voltage and so needs less amplification at the mixer or recording device. This is a practical concern but is not directly an indication of the mic's quality, and in fact the term sensitivity is something of a misnomer, 'transduction gain' being perhaps more meaningful, (or just "output level") because true sensitivity is generally set by the noise floor, and too much "sensitivity" in terms of output level compromises the clipping level. There are two common measures. The (preferred) international standard is made in millivolts per pascal at 1 kHz. A higher value indicates greater sensitivity. The older American method is referred to a 1 V/Pa standard and measured in plain decibels, resulting in a negative value. Again, a higher value indicates greater sensitivity, so −60 dB is more sensitive than −70 dB.

[edit] Measurement microphones

Some microphones are intended for testing speakers, measuring noise levels and otherwise quantifying an acoustic experience. These are calibrated transducers and are usually supplied with a calibration certificate that states absolute sensitivity against frequency. The quality of measurement microphones is often referred to using the designations "Class 1," "Type 2" etc., which are references not to microphone specifications but to sound level meters.[22] A more comprehensive standard[23] for the description of measurement microphone performance was recently adopted.Measurement microphones are generally scalar sensors of pressure; they exhibit an omnidirectional response, limited only by the scattering profile of their physical dimensions. Sound intensity or sound power measurements require pressure-gradient measurements, which are typically made using arrays of at least two microphones, or with hot-wire anemometers.

[edit] Microphone calibration

Main article: Measurement microphone calibration

To take a scientific measurement with a microphone, its precise sensitivity must be known (in volts per pascal). Since this may change over the lifetime of the device, it is necessary to regularly calibrate measurement microphones. This service is offered by some microphone manufacturers and by independent certified testing labs. All microphone calibration is ultimately traceable to primary standards at a national measurement institute such as NPL in the UK, PTB in Germany and NIST in the USA, which most commonly calibrate using the reciprocity primary standard. Measurement microphones calibrated using this method can then be used to calibrate other microphones using comparison calibration techniques.Depending on the application, measurement microphones must be tested periodically (every year or several months, typically) and after any potentially damaging event, such as being dropped (most such mikes come in foam-padded cases to reduce this risk) or exposed to sounds beyond the acceptable level.

[edit] Microphone array and array microphones

Main article: Microphone array

A microphone array is any number of microphones operating in tandem. There are many applications:- Systems for extracting voice input from ambient noise (notably telephones, speech recognition systems, hearing aids)

- Surround sound and related technologies

- Locating objects by sound: acoustic source localization, e.g. military use to locate the source(s) of artillery fire. Aircraft location and tracking.

- High fidelity original recordings

- 3D spatial beamforming for localized acoustic detection of subcutaneous sounds

[edit] Microphone windscreens

Windscreens[note 1] are used to protect microphones that would otherwise be buffeted by wind or vocal plosives from consonants such as "P", "B", etc. Most microphones have an integral windscreen built around the microphone diaphragm. A screen of plastic, wire mesh or a metal cage is held at a distance from the microphone diaphragm, to shield it. This cage provides a first line of defense against the mechanical impact of objects or wind. Some microphones, such as the Shure SM58, may have an additional layer of foam inside the cage to further enhance the protective properties of the shield. One disadvantage of all windscreen types is that the microphone's high frequency response is attenuated by a small amount, depending on the density of the protective layer.Beyond integral microphone windscreens, there are three broad classes of additional wind protection.

[edit] Microphone covers

Microphone covers are often made of soft open-cell polyester or polyurethane foam because of the inexpensive, disposable nature of the foam. Optional windscreens are often available from the manufacturer and third parties. A visible example of an optional accessory windscreen is the A2WS from Shure, one of which is fitted over each of the two Shure SM57 microphones used on the United States president's lectern.[24] One disadvantage of polyurethane foam microphone covers is that they can deteriorate over time. Windscreens also tend to collect dirt and moisture in their open cells and must be cleaned to prevent high frequency loss, bad odor and unhealthy conditions for the person using the microphone. On the other hand, a major advantage of concert vocalist windscreens is that one can quickly change to a clean windscreen between users, reducing the chance of transferring germs. Windscreens of various colors can be used to distinguish one microphone from another on a busy, active stage.[edit] Pop filters

Pop filters or pop screens are used in controlled studio environments to minimize plosives when recording. A typical pop filter is composed of one or more layers of acoustically transparent gauze-like material, such as woven nylon (e.g. pantyhose) stretched over a circular frame and a clamp and a flexible mounting bracket to attach to the microphone stand. The pop shield is placed between the vocalist and the microphone. The closer a vocalist brings his or her lips to the microphone, the greater the requirement for a Pop filter. Singers can be trained either to soften their plosives or direct the air blast away from the microphone, in which cases they don't need a pop filter.Pop filters also keep spittle off the microphone. Most condenser microphones can be damaged by spittle.

[edit] Blimps

Blimps (also known as Zeppelins) are large, hollow windscreens used to surround microphones for outdoor location audio, such as nature recording, electronic news gathering, and for film and video shoots. They can cut wind noise by as much as 25 dB, especially low-frequency noise. The blimp is essentially a hollow cage or basket with acoustically transparent material stretched over the outer frame. The blimp works by creating a volume of still air around the microphone. The microphone is often further isolated from the blimp by an elastic suspension inside the basket. This reduces wind vibrations and handling noise transmitted from the cage. To extend the range of wind speed conditions in which the blimp remains effective, many have the option of a secondary cover over the outer shell. This is usually an acoustically transparent, synthetic fur material with long, soft hairs. Common and slang names for this include "dead cat" or "windmuff". The hairs deaden the noise caused by the shock of wind hitting the blimp. A synthetic fur cover can reduce wind noise by an additional 10 dB.[25]

[edit] See also

- Loudspeaker (the inverse intent of a microphone - to turn transcribed sound into acoustic waves)

- Hydrophone (microphone for underwater use)

- Geophone (microphone for use within the earth)

- Ionophone (plasma-based microphone)

- Microphone connector

- Microphone practice

- Microphone preamplifier

- Microphone stand

- A-weighting

- ITU-R 468 noise weighting

- Nominal impedance — Information about impedance matching for audio components

- Sound pressure level

- XLR connector — The 3-pin variant of which connects microphones

- Shock mount - Microphone mount that suspends the microphone in elastic straps